PCB

除了製造,我們更希望能提升您的市場競爭力

透過在台灣擁有UL、ISO 和 QS 認證的生產線,我們能滿足客戶訂單的種類,從1片的快單,到大量產的訂單。我們知道,PCB打樣階段的效率和準確性是客戶是否能夠領先市場的重要階段,亦是讓最終產品能夠快速度上市的關鍵。因此,不論在哪個階段或是什麼樣的訂單數量,我們總是以始終如一的態度面對客戶每一次的訂單需求。

在許多情況下,透過瞭解客戶的需求,以及對客戶的瞭解,再加上對不同規模產線的整合,我們在製造樣品的階段,就針對客戶量產時可能面對的問題,提供建議跟諮詢,以優化生產效率跟成本,提升客戶整體市場競爭力。

製程能力

Laminate Material

| Base Material |

FR-4 TG135, TG150, TG170 |

| CEM1 |

| CEM3 |

| Rogers 3, 4 and 5 series |

| Arlon |

| Nelco 4000-13 |

| Alμminμm - 2L |

| Ceramic |

| Kapton |

| BT Material |

| Material Thickness |

3~240 mil (0.076mm ~ 6mm) |

| Min. board Thickness |

4mil. (0.1mm) - 2L |

| 14mils (0.4mm) - 4L |

| 24mils (0.6mm) - 6L |

| Max. / Min. Layer |

1 ~ 20L - Mass-Pro. |

| 22 ~ 26 L - Samples |

| Cu. Thickness |

0.3 ~ 10 Oz - Mass-Pro. |

Pattern Design

| Min. Line-width |

3 mils ( 0.076 mm ) -Mass-Production. |

| Min Spacing |

3mils (0.076mm) - Mass-Production |

| Image Distortion |

(+/- 20%) |

| Gold Thickness Range |

3~50μ" |

| Open / Short |

YES |

| Bow & Twist |

0.75% |

Solder mask

| Type Available |

Taiyo, Tamura, Onstatic |

| Green, Black, Blue, Red, White, Purple, Clear |

| Solder mask Registration tol. |

+/-3 mil |

| Min.Width S/M Bridge |

4 mil |

Peelable Mask

| PeelableMask Type |

Peters SD2955, SD2954,SD2952 |

| PeelableMask Thickness |

200μm |

Tolerance

| Routing |

+/- 0.005" |

| Feature to Hole |

+/- 4 mil |

| Hole to Hole |

+/-3 mil |

| Punching |

+/- 4 mil |

V-Cut

| V-grove Depth |

+/-10% |

| Min. Unit / Panel size |

100 mm |

| Min. Unit / Panel thick. |

3.2 mm |

Surface Treatment

| HASL Thickness Range |

80~1000 μm |

| Entek Thickness Range |

0.2~0.3 μm |

| Electroless Nickel Thickness |

100~200 μ" |

| Electroless Gold Thickness |

2~10μ" Max |

| Wire Bonding Gold Thickness |

5~10μ"Max |

| Lead Free HASL |

80~1000 μm |

| Immersion Silver |

6 ~12 μ" |

| Immersion Tin |

30~40 μ"(Include copper) |

| 15~20 μ"(Tin only) |

| Flux Thickness Range |

none |

| Carbon Print Thickness |

per resistor request |

| Carbon Print Res. |

per request |

Drilling

| Min. Final Hole Size |

6 mils ( 0.15 mm ) - Mechnical |

| Size |

4 mils ( 0.1 mm ) -Laser Drill |

| Hole size tol. |

PTH ±3 mil (+/-2mil for Press Fit ) |

| NPTH ±2 mil |

| Hole location tol. |

+/-3 mil |

| Layer to layer |

+/-3 mil |

| Registration tol. |

|

| Fiducial Mark Tolerance |

+/-20% |

| Board flatness Tolerance |

0.75% |

Special Requirement

| Epoxy In Holes |

|

| Vias In pad |

|

| Blind/Buried Vias |

|

QUICK TURN PRICE

Testing and tooling included

The dimensions below are the overall dimension per shipping lot.

Unit is in sq. inch. Currency: USD

Ex: Price of 495 sq. inches two layers board in 4 working days is $390.

Prices are based on standard spec, FR4 (Tg130), 1.6mm, up to 1oz start copper thickness, HASL finished, green solder mask and white silk screen, min. 4/4 mil trace width/space, min via 12 mil.

Lead time:

We start our working day (Monday to Friday) from 8:00am and finish at 20:00pm(Taiwan time). The lead time start from the first working 8:00am and boards will be shipped out before 20:00pm of the last working day. For example, if we receive your 2L job order with over all dimension 1480 Sq inches which requires 3 working days at 19:00 on Monday, we will ship it out no later than 20:00 that Thursday.

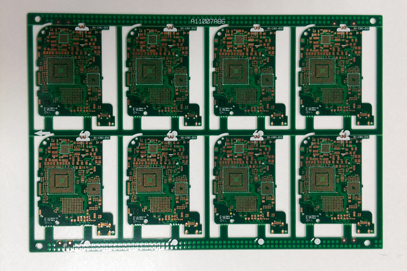

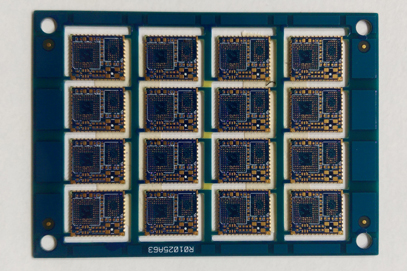

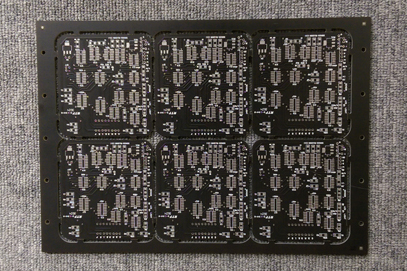

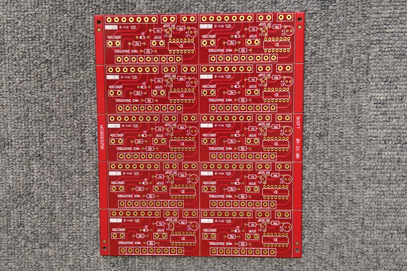

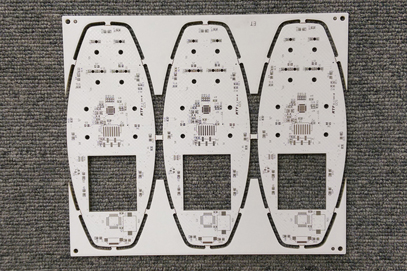

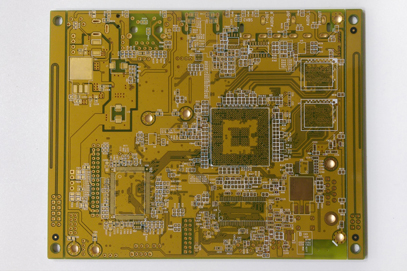

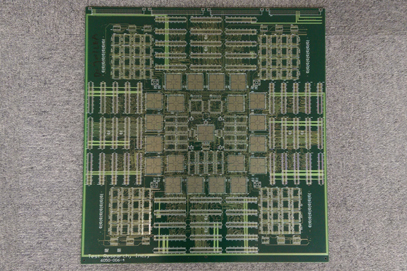

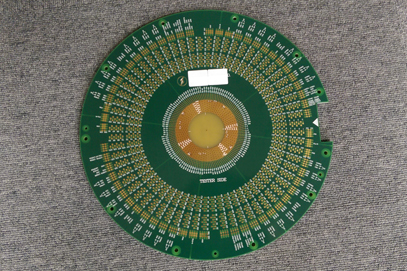

空板樣品

3 mils trace, 3 time lamination, 2 laser drill

Blind and burried via, edge plated,

Impendance control, epoxy filled via

Thick board with 6 mils via